La máquina llenadora de polvo con tornillo sin fin de doble cabezal es un dispositivo utilizado para el llenado preciso de materiales en polvo, ampliamente utilizado en industrias como la farmacéutica, alimentaria y química.

Industria Farmacéutica: Envasado de medicamentos en polvo.

Industria Alimentaria: Envasado de especias, café en polvo y otros productos alimenticios.

Industria Química: Llenado y envasado de polvos químicos.

Este equipo es cada vez más valorado en la fabricación moderna por su capacidad para mejorar la eficiencia de la producción y la calidad del producto.

nombre del producto :

BA-PF double head auger powder filling machineCertificación :

cGMP CE ISO SGS and etc.Tiempo de espera :

15 Days Fast Delivery.Puerto de carga :

Guangzhou/Shenzhen / ShanghaiFunción del producto :

30g~3000gServicio posventa proporcionado :

Engineers available to service machinery overseas.Garantía :

1 YearsCantidad mínima de pedido :

1Descripción general

La línea de máquinas llenadoras de polvo con sinfín de doble cabezal es un sistema integrado diseñado para el llenado eficiente y preciso de productos en polvo en contenedores. Esta línea normalmente consta de múltiples componentes que trabajan juntos para agilizar el proceso de llenado en diversas industrias, incluidas la farmacéutica, la alimentaria y la química.

Componentes clave

1. Máquina llenadora de sinfín de doble cabezal:

El núcleo de la línea, con dos cabezales de sinfín que permiten el llenado simultáneo de dos contenedores, mejorando el rendimiento.

2. Tolva:

Una unidad de almacenamiento que contiene el material en polvo antes de introducirlo en la máquina llenadora. Garantiza un suministro constante de material para un funcionamiento ininterrumpido.

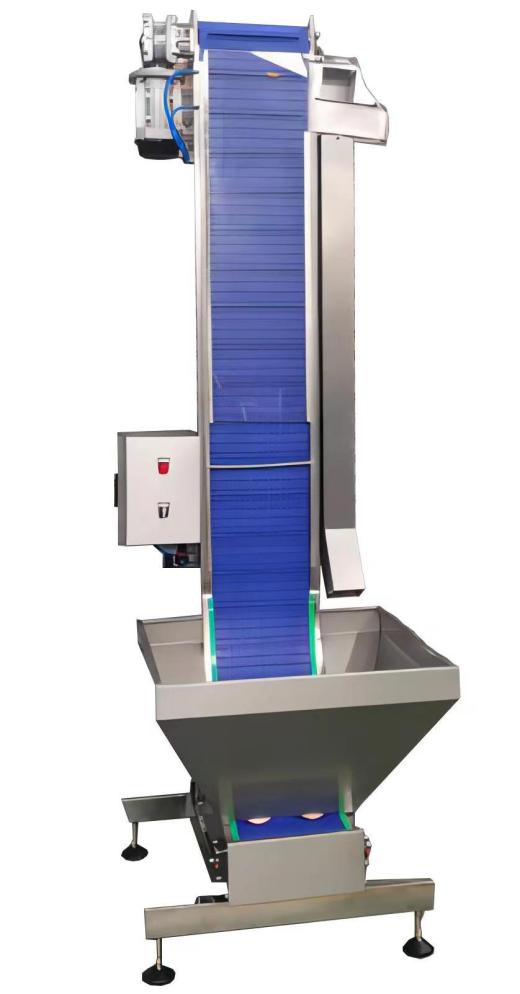

3. Sistema transportador:

Transporta contenedores hacia y desde la máquina llenadora. Este sistema puede incluir cintas transportadoras u otro tipo de transportadores para un movimiento eficiente.

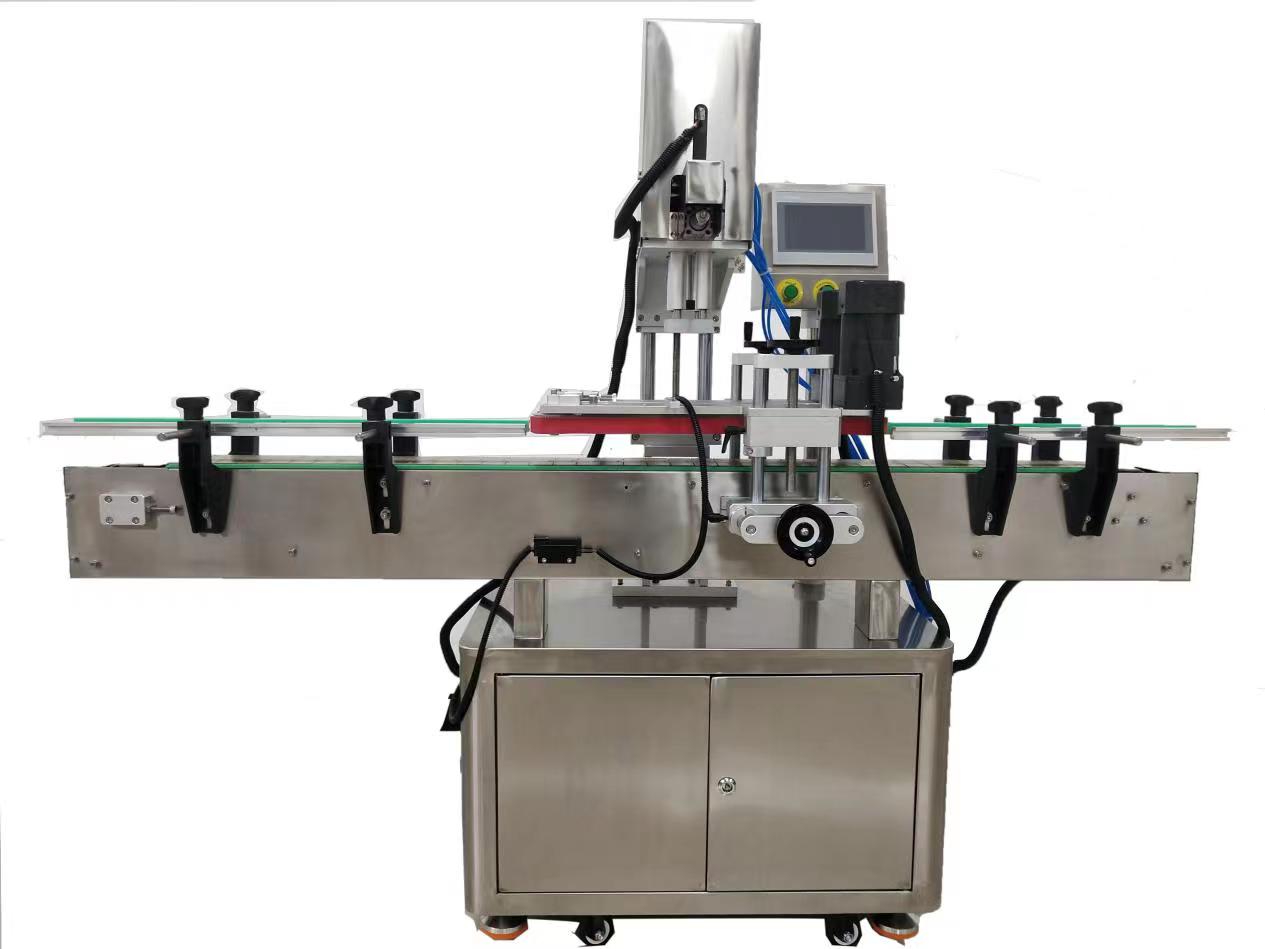

4. Panel de control:

Un sistema de control integrado que permite a los operadores establecer parámetros como la velocidad de llenado, el volumen y los modos de funcionamiento de la máquina. A menudo están equipados con una interfaz de pantalla táctil para facilitar su uso.

5. Máquina taponadora/selladora (opcional):

Tapa o sella automáticamente los contenedores llenos, asegurando la integridad del producto y extendiendo la vida útil.

6. Máquina etiquetadora (opcional):

Aplica etiquetas a los envases después del llenado y sellado, facilitando el cumplimiento de la marca y la información del producto.

Características principales

Características clave de la línea de máquinas llenadoras de polvo con barrena de doble cabezal

1. Diseño de doble cabezal:

Permite el llenado simultáneo de dos contenedores, aumentando significativamente la eficiencia de producción.

2.Relleno de alta precisión:

Equipado con sensores y sistemas de control avanzados para garantizar volúmenes de llenado precisos y consistentes.

3. Tolva versátil:

Una tolva de gran capacidad que puede acomodar diversos materiales en polvo, lo que garantiza un suministro constante para un funcionamiento continuo.

4. Panel de control fácil de usar:

Cuenta con una interfaz de pantalla táctil para una fácil operación, lo que permite ajustes rápidos a los parámetros de llenado.

5. Velocidad de llenado ajustable:

Permite a los operadores personalizar la velocidad de llenado según los requisitos de producción, mejorando la flexibilidad.

6. Sistema transportador automático:

Transporta contenedores de manera eficiente hacia y desde la estación de llenado, reduciendo la manipulación manual y mejorando el flujo de trabajo.

7. Diseño higiénico:

Construido con materiales que cumplen con los estándares de higiene de la industria, lo que lo hace fácil de limpiar y adecuado para aplicaciones alimentarias y farmacéuticas.

8. Tapado y etiquetado opcionales:

Se puede integrar con máquinas tapadoras y etiquetadoras para agilizar todo el proceso de envasado.

Estas características hacen que la línea de máquinas llenadoras de polvo con sinfín de doble cabezal sea una opción eficiente y confiable para operaciones de llenado de polvo de gran volumen en diversas industrias.

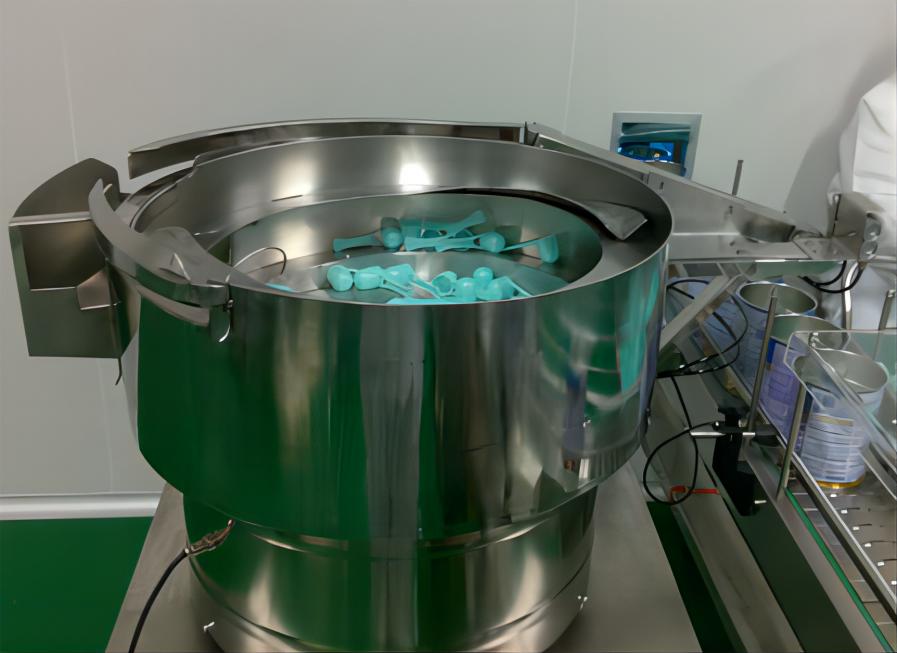

Tolva de escupitajo nivelada

Tipo de tornillo

Tipo de acero inoxidable

Sensor de nivel automático

Volante

Alimentador de tornillo

Cuchara automática alimentación máquina

Tapa levantador

Máquina selladora continua de papel de aluminio (sellado por inducción electromagnética)

Máquina taponadora

Etiquetadora de botellas redondas

Sinfines y tubos de perforación

Principales parámetros técnicos

Máquina llenadora de sinfín automática de dos cabezales

Especificación de embalaje: | 30g~3000g (es necesario cambiar la espiral) |

Precisión de embalaje: | ±0,5-1% |

Materiales aplicables: | polvo |

Velocidad de embalaje teórica: | 3~25 latas/minuto |

Esfuerzo de torsión: | 10 N/M |

Velocidad nominal: | 1500 rpm |

Par/velocidad: | sin cambios |

Potencia del servomotor: | 1,5 kw |

Potencia del motor de agitación: | 0,4 kw |

Largo, ancho y alto del contorno: | 3000*850*2100 (altura personalizada con la altura de la botella y la línea transportadora) |

Potencia de la máquina principal: | 1,9 kw |

Certificados y Fábrica

Fogonadura